PVDF Aluminum Profile refers to a type of aluminum profile that is coated with PVDF (Polyvinylidene fluoride) coating. PVDF is a highly durable and weather-resistant coating that provides protection against UV rays, corrosion, and fading. PVDF-coated aluminum profiles are commonly used in architectural applications, such as building facades, curtain walls, roof edges, and decorative elements. They offer excellent color retention, gloss retention, and resistance to dirt and stains, making them ideal for outdoor use in various climates. Additionally, PVDF aluminum profiles can be customized in terms of shape, size, and color to meet specific design requirements.

It is commonly used in various industries, such as construction, automotive, and furniture, for applications such as window frames, doors, curtain walls, and architectural structures.

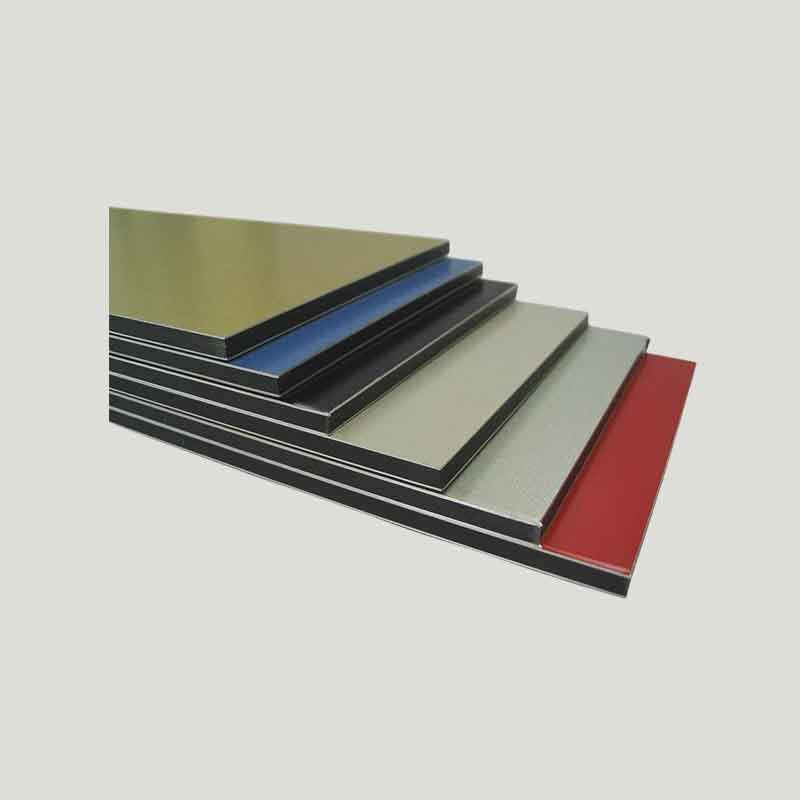

PVDF aluminum profile coating offers a wide range of color options and finishes, allowing for customization and enhancing the overall appearance of the aluminum profiles. The coating also provides a smooth and glossy surface, giving a premium look to the profiles.

PVDF coating provides exceptional resistance to harsh weather conditions, including extreme temperatures, rain, snow, and sunlight. This makes PVDF aluminum profiles suitable for both indoor and outdoor applications.

PVDF aluminum profile are highly resistant to corrosion, making them ideal for use in environments with high humidity, saltwater exposure, or chemical exposure. This extends the lifespan of the profiles and reduces maintenance requirements.

PVDF aluminum profile on aluminum profiles is easy to clean and maintain. The smooth surface prevents dirt and dust from adhering to the profiles, and any stains or marks can be easily wiped off with a mild detergent and water.

Milled aluminum profile is a cost-effective material compared to other metals like steel or titanium. Milled aluminum profiles offer a cost-effective solution for applications that require high strength and durability without the added expense of other materials.

| Certificate and Standard | ISO9001, ISO14001, OHSAS18001, Qualicoat, CQC Energy-Saving Products |

| Material | 6000 series: 6063, 6061 |

| Temper | T4, T5, T6 |

| Thickness | General extrusion thickness: 0.6 – 5.0 mm |

| Length | 3m or 6m per piece. Customized request available |

| Finishes | Mill, anodized, powder coated, electrophoresis, wood grain, timber, PVDF paint, polish, brushed |

| Deep Process | CNC, drilling, milling, cutting, welding, bending, assembling |

| Production Capacity | 300000 tons annually. |

| Packing Details | pearl cotton with carton paper |

| Payment Terms | T/T 50% for deposit, balance before delivery |

Anodized aluminum profiles are commonly used in architectural applications such as window frames, door frames, curtain walls, and façade cladding. The anodized finish provides a durable and corrosion-resistant surface that can withstand harsh weather conditions.

Anodized aluminum profiles find extensive use in the automotive industry for various applications such as trim, moldings, and decorative parts. The anodized finish enhances the aesthetic appeal of the vehicle while providing protection against scratches and corrosion.

Anodized aluminum profiles are utilized in the furniture and interior design industry for applications such as handles, frames, and decorative trims. The anodized finish offers a wide range of color options and a sleek appearance.

Anodized aluminum profiles are used in the electronics and electrical industry for components such as heat sinks, enclosures, and mounting brackets. The anodized finish improves heat dissipation and provides electrical insulation properties.

Measure and Mark

Measure and mark the desired location for the profile on the wall or surface where it will be installed.

Prepare the Surface

Ensure that the surface is clean, dry, and free from any dust or debris. Use a clean cloth or brush to remove any dirt or particles.

Cut the PVDF Aluminum Profile

Cut the PVDF aluminum profile to the desired length using a saw or a profile cutting machine. Make sure to wear appropriate safety gear, such as goggles and gloves, when cutting the profile.

Apply Adhesive or Sealant

Apply a suitable adhesive or sealant to the back of the profile. Ensure that the adhesive is compatible with both the PVDF coating and the surface material.

Press the Profile

Press the profile firmly onto the marked location on the wall or surface. Apply even pressure to ensure proper adhesion.

Hold in Place

Use clamps or tape to hold the profile in place while the adhesive cures. Follow the manufacturer’s instructions for the recommended curing time.

Check Alignment and Stability

Once the adhesive has cured, remove any clamps or tape and check the profile for proper alignment and stability.

Repeat for Additional Profiles

Repeat the above steps for any additional PVDF aluminum profiles that need to be installed.

We are manufacture,we have 14 years experience for supply Metal material and products in domestic.

For smal toolino (Extemal size less than 229mm). t takes about 10-15 days for tooling and about 5 davs for of-tol samples preparino.

We can supply the free sample,but the sample express freight should be by you.

Yes, we will keep you updated about the status here by sending videos or pictures.

You can start with a small trial. Just send me your drawings!

Look forward to hearing from you.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy