Powder coating aluminum profile is a process of applying a dry powder paint onto the surface of an aluminum profile. The aluminum profile is first cleaned and pre-treated to ensure proper adhesion of the powder coating. Then, the powder paint is electrostatically charged and sprayed onto the profile. The charged powder particles adhere to the grounded aluminum surface and form a uniform coating. The coated profile is then heated in an oven, where the powder particles melt and fuse together to create a durable and protective finish. Powder coating aluminum profiles provides excellent corrosion resistance, weather resistance, and aesthetic appeal.

It is commonly used in various industries, such as construction, automotive, and furniture, for applications such as window frames, doors, curtain walls, and architectural structures.

Powder coating aluminum profile provides a strong and durable finish that is resistant to chipping, scratching, and fading. This makes it ideal for outdoor applications where the aluminum profiles are exposed to harsh weather conditions.

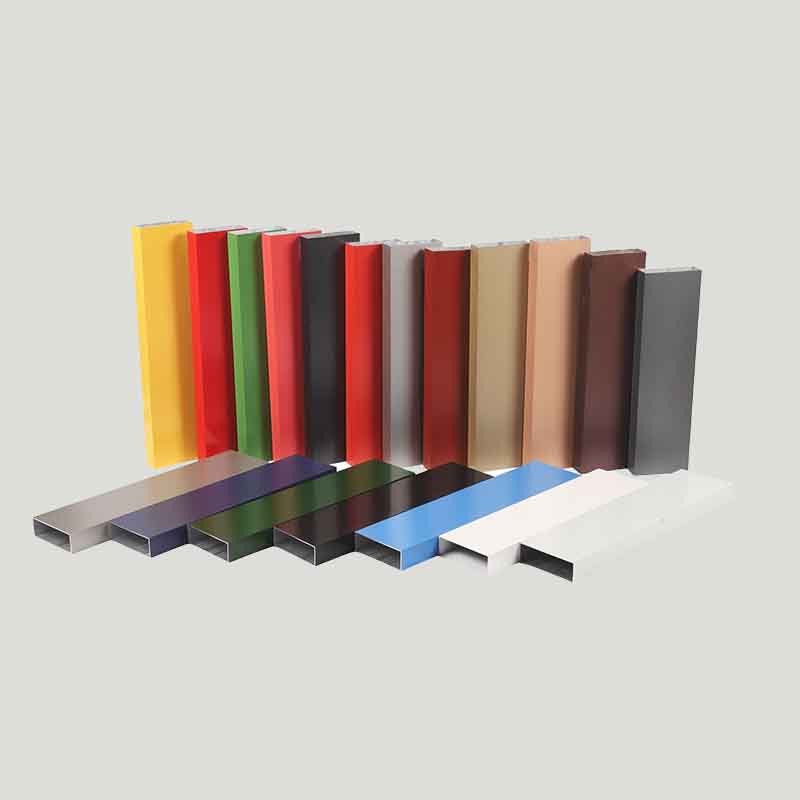

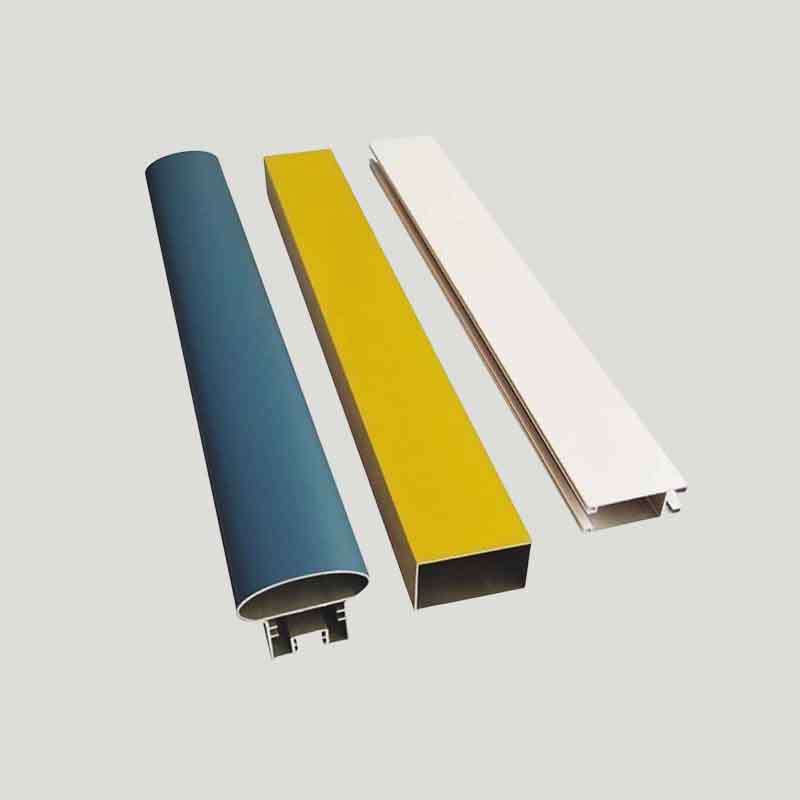

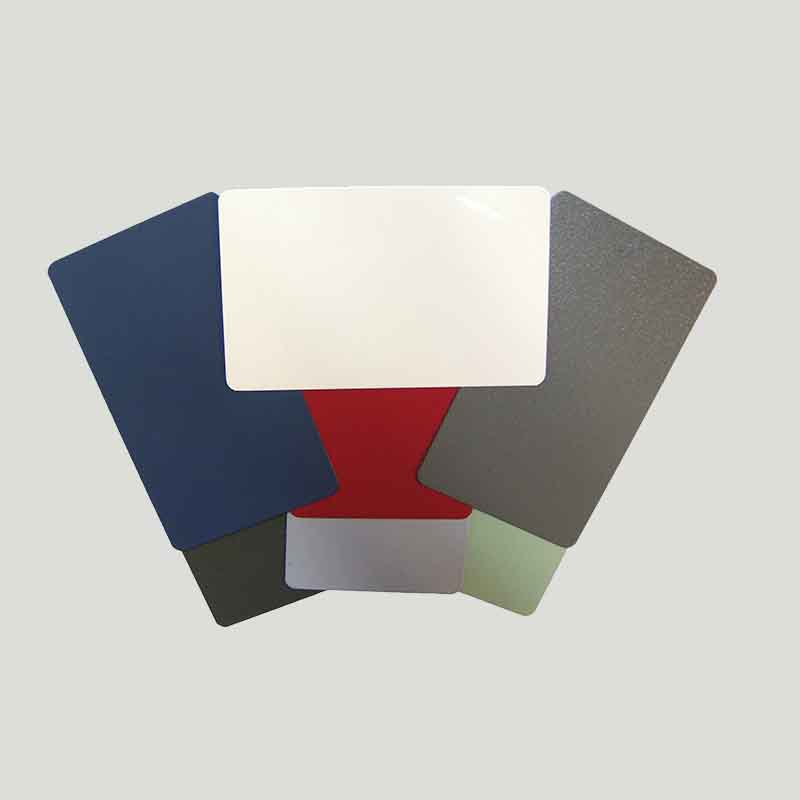

Powder coating offers a wide range of colors and finishes, allowing for customization and enhancing the appearance of the aluminum profiles. It provides a smooth and even finish, giving a high-quality look to the product.

Powder coating is an environmentally friendly coating option as it does not contain volatile organic compounds (VOCs) or other hazardous materials. Powder coating aluminum profile produces less waste and has a higher transfer efficiency, reducing the amount of coating material wasted during the application process.

Powder coating aluminum profiles are susceptible to corrosion, especially when exposed to moisture or chemicals. Powder coating acts as a protective barrier, preventing corrosion and extending the lifespan of the aluminum profiles.

Milled aluminum profile is a cost-effective material compared to other metals like steel or titanium. Milled aluminum profiles offer a cost-effective solution for applications that require high strength and durability without the added expense of other materials.

| Certificate and Standard | ISO9001, ISO14001, OHSAS18001, Qualicoat, CQC Energy-Saving Products |

| Material | 6000 series: 6063, 6061 |

| Temper | T4, T5, T6 |

| Thickness | General extrusion thickness: 0.6 – 5.0 mm |

| Length | 3m or 6m per piece. Customized request available |

| Finishes | Mill, anodized, powder coated, electrophoresis, wood grain, timber, PVDF paint, polish, brushed |

| Deep Process | CNC, drilling, milling, cutting, welding, bending, assembling |

| Production Capacity | 300000 tons annually. |

| Packing Details | pearl cotton with carton paper |

| Payment Terms | T/T 50% for deposit, balance before delivery |

Anodized aluminum profiles are commonly used in architectural applications such as window frames, door frames, curtain walls, and façade cladding. The anodized finish provides a durable and corrosion-resistant surface that can withstand harsh weather conditions.

Anodized aluminum profiles find extensive use in the automotive industry for various applications such as trim, moldings, and decorative parts. The anodized finish enhances the aesthetic appeal of the vehicle while providing protection against scratches and corrosion.

Anodized aluminum profiles are utilized in the furniture and interior design industry for applications such as handles, frames, and decorative trims. The anodized finish offers a wide range of color options and a sleek appearance.

Anodized aluminum profiles are used in the electronics and electrical industry for components such as heat sinks, enclosures, and mounting brackets. The anodized finish improves heat dissipation and provides electrical insulation properties.

Prepare the Aluminum Profiles

Start by cleaning the aluminum profiles thoroughly to remove any dirt, grease, or other contaminants. Use a mild detergent and water solution or a specialized aluminum cleaner. Rinse the profiles with clean water and allow them to dry completely.

Pre-treat the Aluminum Profiles

Apply a chemical pre-treatment to the aluminum profiles to enhance adhesion and corrosion resistance. This step typically involves using a chromate conversion coating or a phosphate-based treatment. Follow the manufacturer’s instructions for the specific pre-treatment product you are using.

Apply the Powder Coating

Once the pre-treatment is complete and the aluminum profiles are dry, it’s time to apply the powder coating. Powder coating is a dry finishing process where powder paint is electrostatically applied to the aluminum profiles. Use a powder coating gun to evenly spray the powder onto the profiles, ensuring that they are completely covered.

Cure the Powder Coating

After applying the powder coating, the aluminum profiles need to be cured to create a durable and smooth finish. Place the coated profiles in a curing oven and heat them to the specified temperature and duration recommended by the powder coating manufacturer. This process allows the powder to melt and flow, forming a protective and decorative coating.

Align and Position the Profile

Place the profile back into position and align the mounting holes with the pilot holes. Make sure it is level and centered before proceeding.

Insert Mounting Screws

Insert the mounting screws through the profile’s mounting holes and into the pilot holes. Use a screwdriver or a drill with a screwdriver bit to tighten the screws securely.

Repeat for Additional Profiles

Repeat the process for any additional profiles that need to be installed.

We are manufacture,we have 14 years experience for supply Metal material and products in domestic.

For smal toolino (Extemal size less than 229mm). t takes about 10-15 days for tooling and about 5 davs for of-tol samples preparino.

We can supply the free sample,but the sample express freight should be by you.

Yes, we will keep you updated about the status here by sending videos or pictures.

You can start with a small trial. Just send me your drawings!

Look forward to hearing from you.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy