Aluminum is an amazing material that has impacted nearly every major industry over the past century. That includes the medical industry and the many devices that are transforming healthcare as we know it. Thanks to aluminum, people all over the world are living longer, healthier lives. Today we’ll be looking at what aluminum alloys can commonly be found in the medical industry and why they offer so many advantages.

Medical care is an industry that has very little margin for error. Lives are literally at stake. For any material to be deemed fit for medical devices, it must meet very high standards of performance and reliability. A factor not always considered in other industries is that medical devices, tools and equipment must have very high sanitation levels. This is an area where aluminum particularly excels.

If you work in the medical industry or are manufacturing products intended for medical use, you need to be sure that any aluminum you source is of the highest quality. That’s why it always pays to work with a trusted supplier with a proven track record of success.

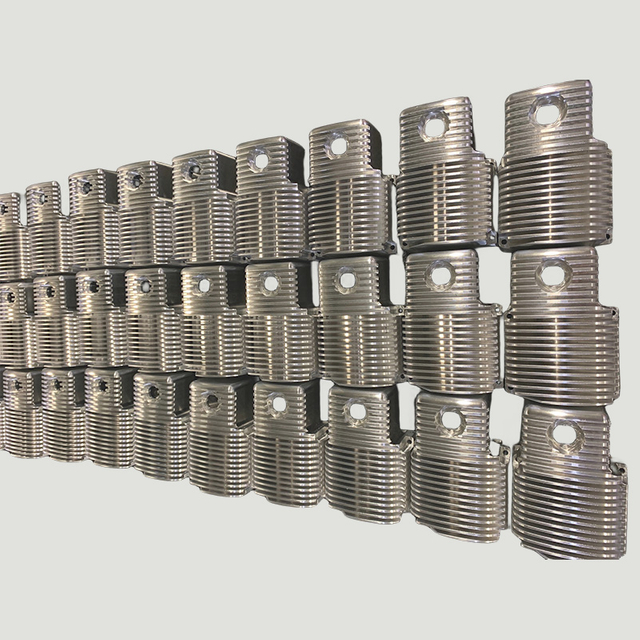

| Service | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding | ||||||

| Materials Aluminum | 2000 series, 6000 series, 7075, 5052, etc. | ||||||

| Stainless steel | SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | ||||||

| Steel | 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||||||

| Brass | 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | ||||||

| Titanium | GradeF1-F5 | ||||||

| Plastic | Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | ||||||

| Surface Treatment | Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. | ||||||

| Tolerance | +/-0.002~+/-0.005mm | ||||||

| Surface Roughness | Min Ra0.1~3.2 | ||||||

| Drawing Accepted | Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF, or Samples | ||||||

| OEM customized aluminum profiles are available | |||||||

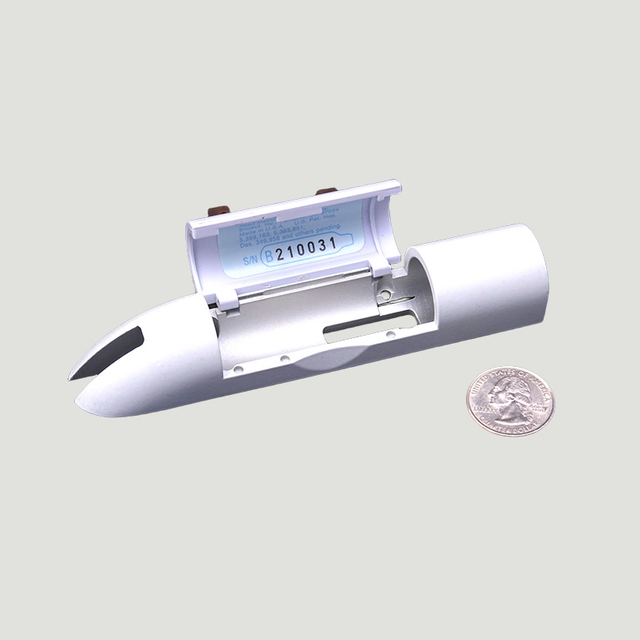

Many of the same benefits that make aluminum so desirable in modern industries such as architecture, aerospace and tech are also useful for the medical industry. Most obviously, aluminum is extremely lightweight and has one of the best strength-to-weight ratios of any metal. This means that equipment made from aluminum can be thin, light and flexible, yet still be extremely strong and durable. Very few other materials can match aluminum in this regard.

Another advantage of aluminum is its formability. Devices made from aluminum can easily be fabricated to whatever form is desired, making it useful for medical devices that must be fashioned to exact specifications. This is especially true for therapeutic and prosthetic equipment and devices that are custom fit to a patient. Aluminum, with its exceptional design flexibility, has helped make modern advances in medical devices possible.

Aluminum is also prized for its excellent corrosion resistance. This is critical in the medical industry where sanitation and cleanliness are necessary. Medical equipment is often exposed to bodily fluids, heavy-duty cleaners and other corrosive liquids; aluminum’s ability to withstand corrosion is a perfect match. In fact, aluminum has a natural ability to form what is known as a passivation layer that protects aluminum even if it becomes nicked or scratched.

Other benefits of aluminum that make it suitable for medical devices includes its machinability, recyclability and the fact it does not require a large investment to machine and fabricate, making it a cheaper alternative to some other high performance materials such as stainless steel.

Our normal thickness is about 10 um. Yes, we can do 15um and above.

We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy