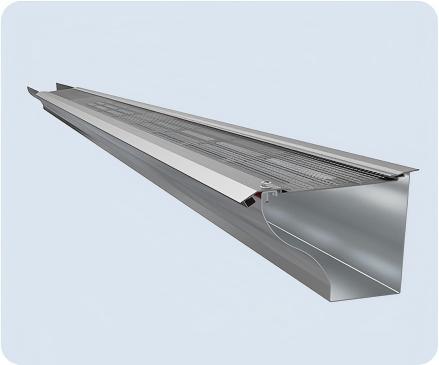

This is a heated rain gutter filter, designed to enhance safety during winter months in North America. Its innovative heating feature accelerates snow melting, significantly reducing the risk of ice falling from gutters. Ideal for university campuses, this product ensures a safer environment in icy conditions.

Structural Damage: lce dams can lead to structural damage tothe roof,especially if the water seeps into cracks and expandsupon freezing. This canweaken the roof’s integrity over time

Brilliance patented product was designed by professional Canadian gutter installers. It is easy to install by homeowners and professionals. Both roll forming aluminum sheet gutter guards and extrusion aluminum profiles and SS mesh gutter guards are available. Brilliance gutter guards is made with very strong structure and different dimension of meash, suitable for different leafs and other debris filter.

The ice dam caused water leakage on the ceiling.

The sink is heated, quickly melting the snow and ensuring smooth drainage.

Rainwater tends to overflow and form icicles.creating potential safety hazards

The eave is heightened by 5cm with a slopeddesign,preventing rainwater from forming icicles.

Self-limiting temperature control heating tapes, also known as self-regulating self-temperature control heating tapes, can autonomously adjust the local heating power of the heating tape according to temperature changes under normal working conditions. As shown in the figure, when the working voltage is applied to the busbar, the conductive carbon particles in the semiconductor core tape form a current path between the busbars. When the temperature rises, the semiconductor core tape expands, reducing the current path and lowering the power; conversely, the power increases. The conductive carbon particles in the semiconductor core tape are extremely tiny, and this regulation mechanism exists in every complete structure of the self-limiting temperature control heating tape. Therefore, in situations where precise temperature control is not required, self-limiting temperature control heating tapes can be used without a temperature controller. Within the length of use, any cutting and connection will not affect its heating structure, and it can be overlapped without causing overheating and damaging its heating structure.

This product is a domestic advanced technology introduced by our company. The core of its technology is to produce the self-limiting temperature body tape in one step by extruding the conductor and the low-resistance transition layer, semiconductor core belt, and inner insulation layer wrapped around the conductor. It uses a three-layer co-extrusion technology. Due to the tight structure of the insulation layer inside the semiconductor core belt, it reduces the influence of air, water, oil, and impurities on each layer of the semiconductor core belt, thereby reducing the attenuation rate and starting current of the semiconductor core belt and increasing the service life of the self-limiting temperature heating tape.

| Product Name | Low Temperature Self-limiting Electric Belt | Medium Temperature Self-limiting Electric Belt | High Temperature Self-limiting Electric Belt |

|---|---|---|---|

| Electric Conductor | Tinned copper wire | Tinned copper wire | Tinned copper and tin stranded wire |

| Thermal Body Materials | Polymer PTC Conductive Composite | Polymer PTC Conductive Composite | Polymer PTC Conductive Composite |

| Major Insulation Materials | Flame retardant/non-flame retardant polyolefin or fluoropolymer | Flame retardant/non-flame retardant polyolefin or fluoropolymer | Flame retardant/non-flame retardant polyolefin or fluoropolymer |

| Wire Sheathing | Aluminum magnesium alloy wire or tinned copper wire | Aluminum magnesium alloy wire or tinned copper wire | Aluminum magnesium alloy wire or tinned copper wire |

| Standard Sheath | Flame retardant/non-flame retardant polyolefin or fluoropolymer | Flame retardant/non-flame retardant polyolefin or fluoropolymer | Flame retardant/non-flame retardant polyolefin or fluoropolymer |

| Minimum Bending Radius | Five times the thickness of the tropopause | Five times the thickness of the tropopause | Five times the thickness of the tropopause |

| Minimum Installation Temperature | -40 | -40 | -40 |

| 10°C Nominal Power | 65 | 105 | 120 |

| Maximum Tolerated Temperature | 85 | 135 | 170 |

| 10°C Nominal Power (Length/watt) | 10/15/20/25/30/W/m | 30/35/45/60/W/m | 25V/30/35/45/65/W/m |

| Explosion-proof Sign | Exe IIC T4 Gb | Exe IIC T4 Gb | Exe IIC T4 Gb |

Our normal thickness is about 10 um. Yes, we can do 15um and above.

We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy