Global Aluminum Gutter Guard Buying Guide

This guide helps B2B buyers around the world. It covers where to buy aluminum gutter guards, typical specs and finishes, customization and machining, quality checks, lead times, and how to get quotes and samples fast. If you search “where to buy aluminum gutter guards” or “aluminum gutter guard supplier,” this guide will help.

Why Choose Aluminum Gutter Guards

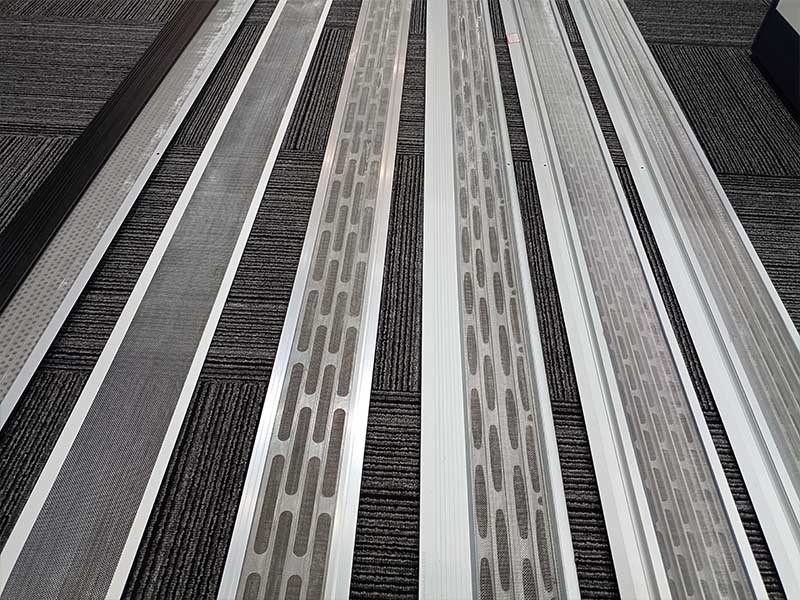

Aluminum guards are light and resist corrosion, especially after anodizing or powder coating. They have good strength and stiffness. They are easy to punch, bend and join. Aluminum is recyclable. Use anodizing plus a high-durability coating or heavier alloy in coastal or very corrosive environments.

Common uses: residential and commercial roof gutters, anti-clog systems, landscape and balcony drainage.

See our product line at Aluminum Gutter Guard.

Where to Buy Aluminum Gutter Guards

Main channels:

- Direct manufacturers — best for lowest cost and custom orders. Typical origins include China (Guangdong/Zhejiang), India, Turkey, Vietnam, Poland and the US.

- B2B platforms and wholesale markets — useful to compare suppliers and MOQ quickly.

- Authorized distributors and brands — offer stock, warranty and local service.

- Roofing system suppliers — good when you need full system integration.

- Trading companies and sourcing agents — they help with language, inspection and logistics for first-time importers.

- Trade shows — find new suppliers and request samples on site.

To become a partner or learn about agency terms, review our Agent Policy. For product details, visit Aluminum Gutter Guard.

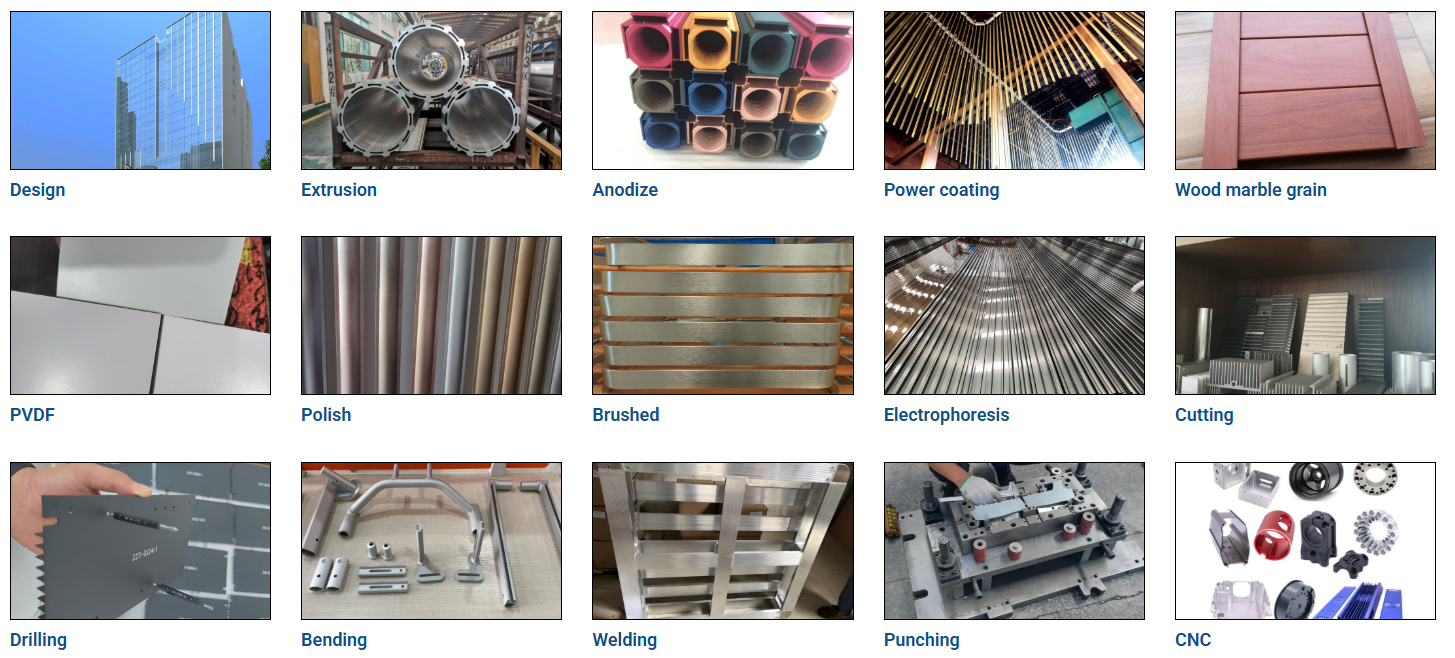

Customization & Machining Capabilities Suppliers Should Offer

Look for suppliers who offer:

- Punching in many hole patterns (round, slotted, diamond).

- Bending, laser cutting, joining by welding or riveting.

- Edge folding, seal treatment and assembly options.

- Production from CAD/DWG with sample before full run.

- Surface color and finish options.

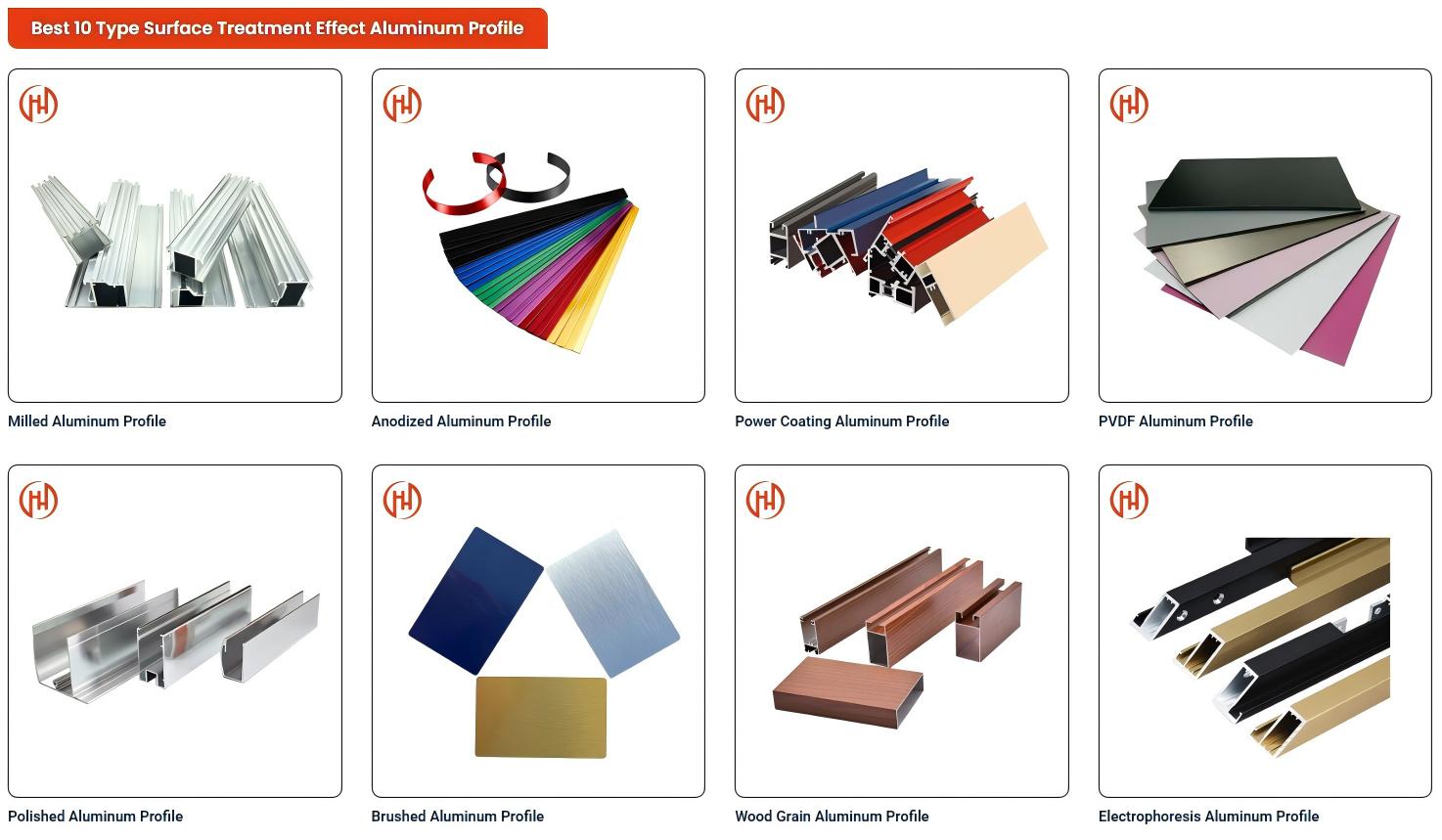

Common finishes: anodizing, powder coating, PVDF, sandblasting and fluorocarbon coatings for high weather resistance.

We support full custom manufacturing and offer Aluminum Machining and CNC Parts services.

Technical Specs — Materials, Thickness & Finishes

| Item | Common Options |

|---|---|

| Alloy | 6063-T5, 6061 (choose by strength and machining needs) |

| Thickness | 0.8 – 1.5 mm (can use thicker for higher load) |

| Tolerances | Thickness ±0.05–0.1 mm; hole position ±0.2–0.5 mm (negotiable) |

| Finishes | Anodizing (5–20 µm), Powder Coating (60–100 µm), PVDF / Fluorocarbon |

| Accessories | Rubber seals, waterproof adhesives, brackets, rivets/bolts |

For more about finishes, see Surface Treatment Effect. For profiles and raw material options, see Aluminum Profile.

Quality, Certification & Inspection

Typical certifications: ISO 9001, ISO 14001, ISO 45001 / OHSAS as needed.

Ask for material certificates, salt spray tests, adhesion tests and mechanical tests. Suppliers often provide factory inspection (FQC) and accept third-party inspection (SGS, BV, Intertek).

Relevant documentation is available on our Product Documents Download page.

How to Buy & Pricing Factors

When you request a quote, include:

- Alloy and grade (e.g., 6063-T5)

- Thickness (mm)

- Dimensions or per-meter requirement

- Hole type, size and spacing

- Surface finish and color

- Quantity and delivery schedule

- Destination port and packaging needs

- Sample and certification needs

Sample orders are common. Lead time for samples: usually 3–7 days. MOQ: samples 1–10 pcs; batch MOQ often 100–500 pcs or by linear meter depending on complexity.

Typical lead times: stocked items 7–21 days; custom orders 10–45 days. Factors that affect price: aluminum market, thickness, punching density, finishing method, quantity, packaging, inspections and certification needs.

See our Latest Catalog for reference pricing and product lines.

Logistics & Delivery

Transport modes: sea (FCL/LCL), air (urgent), courier (samples).

Packaging: moisture-proof film + carton/plywood box + pallet. Add extra protection for sea shipments against salt spray.

Export docs: commercial invoice, packing list, certificate of origin, test reports, bill of lading. For large orders, full containers (FCL) usually save costs. Consider regional warehousing to speed replenishment.

Channel Comparison

| Channel | Pros | Cons |

|---|---|---|

| Factory Direct | Lowest price, full customization, direct certificates | Requires quality checks and payment controls |

| B2B Platforms | Fast supplier comparison | Must verify supplier claims |

| Distributors / Agents | Quick delivery, local support | Higher unit price |

| Trading Companies | One-stop service (inspection, logistics) | Service fee included in price |

Examples & Use Cases

Residential eaves: 6063-T5, 1.0 mm, anodized, 3 mm holes spaced 6 mm.

Commercial roof anti-clog: 1.2–1.5 mm, powder or PVDF coating, reinforced fixing brackets.

Seaside piers: 6061/6063, PVDF plus anodize pre-treatment, salt spray > 500 hours.

See real projects at Applications and installation videos at Video.

Quick RFQ Template

| Required Info | Example / Notes |

|---|---|

| Drawings | DWG / PDF / STEP |

| Material | Example: 6063-T5 |

| Thickness | mm |

| Size | Length × Width or per meter |

| Hole pattern | Shape / diameter / spacing |

| Surface finish | Anodize / Powder / PVDF + color |

| Quantity | Total and split deliveries |

| Destination | Port / Country |

| Samples | Yes / No |

| Certs required | ISO / SGS / RoHS / CE |

| Lead time & payment | Expected delivery and terms |

Submit RFQ and sample requests via Sample Request / Contact.

FAQ

Question: Where do global buyers buy aluminum gutter guards?

Answer: Buyers use factory direct, B2B platforms, distributors, trading companies and trade shows. For first orders ask for samples and certificates.

Question: What alloys and finishes are common?

Answer: Alloys: 6063 and 6061. Thickness: 0.8–1.5 mm. Finishes: anodizing, powder coating, PVDF/fluorocarbon.

Question: Can hole patterns and sizes be customized?

Answer: Yes. Most factories punch, bend and cut to your drawings. Provide CAD files and quantities.

Question: How to get quotes and samples quickly?

Answer: Share drawings, quantity, destination port and finish. Samples usually ship in 3–7 days and may be chargeable or deducted from the first order.

Question: What are typical lead times and MOQ?

Answer: Samples 1–10 pcs. MOQ often 100–500 pcs or by meter. Custom lead time 10–45 days depending on complexity.

Question: What quality assurances and certifications exist?

Answer: ISO 9001, material certificates, salt spray and adhesion tests. Third-party inspection by SGS, BV or Intertek is common. See document downloads at Product Documents Download.

Sample RFQ Email (Example)

Subject: RFQ — Aluminum Gutter Guard (6063-T5, 1.0 mm, Anodized) — Quote & Samples

Body should include company name and contact, drawings, material and thickness, dimensions and hole pattern (see attachments), surface finish (anodized, natural), quantity (e.g., 1,000 pcs split into 2 batches), destination port (Rotterdam / Shanghai), expected lead time (first batch within 6 weeks), sample request (2 pcs, chargeable), payment terms (T/T 30/70 or L/C), and required certificates (material cert + salt spray).

Closing & Next Step

If you need help sourcing suppliers, asking for quotes, arranging third-party inspection or testing, upload drawings and your procurement list. Contact us now via Sample Request / Contact to start. For catalogs and price references see our Latest Catalog. For product documents and reports visit Product Documents Download.