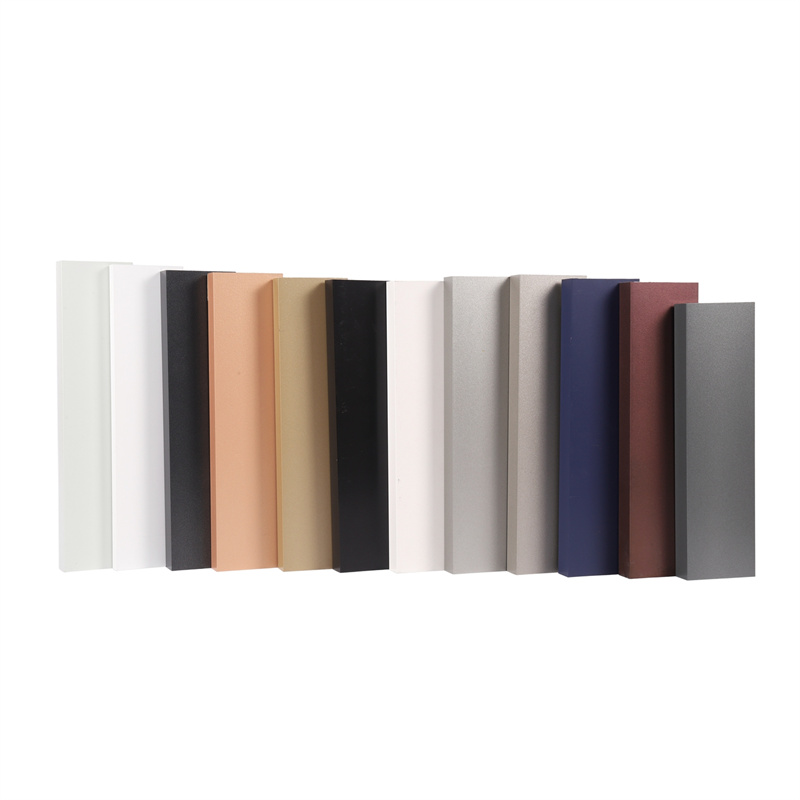

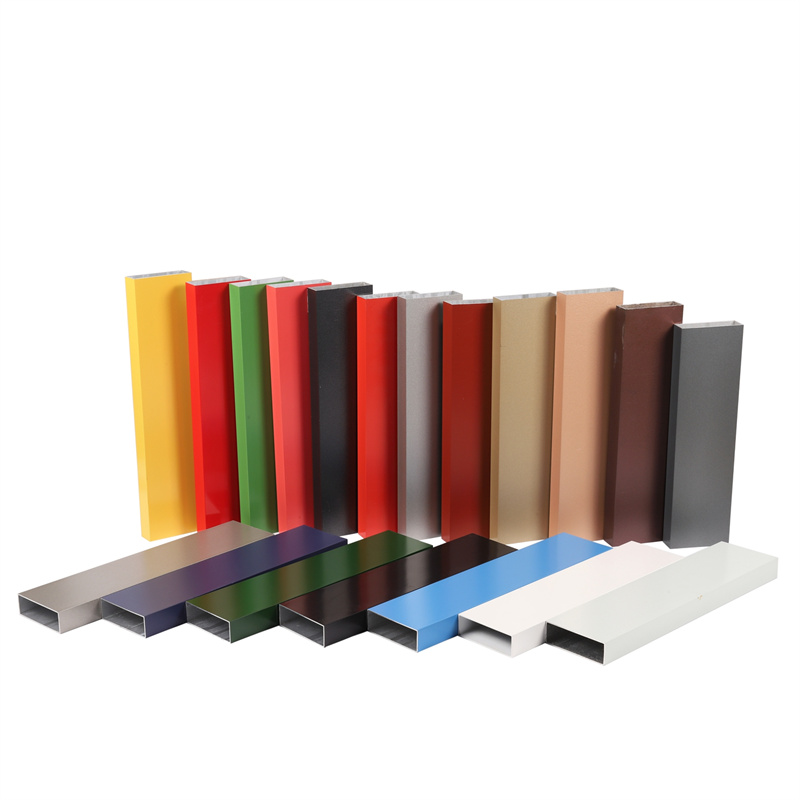

Aluminum fluorocarbon spraying is a commonly used surface treatment technology to improve the corrosion resistance and aesthetics of aluminum alloy products. It is sprayed on the surface of the aluminum alloy of fluorocarbon resin coatings to form a protective layer of uniform, dense, and strong weather resistance.

Aluminum -aluminum fluorocarbon spraying has the following characteristics:

Corrosion resistance: Fluorocarbon resin coating has excellent corrosion resistance and can effectively prevent the surface of aluminum alloy from being oxidized, corrosive and chemical.

Weighing: Fluorocarbon resin coating can maintain color stability and gloss for a long time, and it is not easy to be affected by the external environment such as ultraviolet rays, sour rain, and pollutants.

Abrasion resistance: Fluorocarbon resin coating has high hardness and abrasion resistance, which can effectively prevent the surface of aluminum alloy scratch, wear and wear.

Temperature resistance: Fluorocarbon resin coating can maintain stability at high temperatures, and it is not easy to change color, fall off and deform.

We provide comprehensive aluminum solutions, including design, extrusion, anodizing, powder coating, and various finishes like wood grain and PVDF. Our services also encompass cutting, drilling, bending, welding, punching, and CNC machining, tailored to meet diverse customer needs. Choose our solutions to streamline your project workflow and boost efficiency.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy