You are here: Home / Customized / Power coating process of aluminium profile

Aluminum alloy powder coating is a surface treatment process used to enhance the performance and appearance of aluminum alloy components. The process involves applying a layer of powdered aluminum alloy onto the surface of the substrate using a spray gun. The coated surface is then heated to a high temperature, causing the powder to melt and form a durable and protective coating.

There are several important considerations to keep in mind when performing aluminum alloy powder coating. Firstly, it is crucial to properly clean and prepare the substrate before applying the powder. Any dirt, grease, or oxide layers on the surface should be removed to ensure good adhesion of the coating.

Secondly, the selection of the powder material is important. Different aluminum alloy powders have different properties, such as hardness, corrosion resistance, and heat resistance. The choice of powder should be based on the specific requirements of the application.

Thirdly, the spraying process should be conducted in a controlled environment to avoid contamination. Dust, moisture, and other impurities can negatively affect the quality of the coating. Therefore, a clean and well-ventilated spray booth is recommended.

Additionally, proper curing of the coating is essential for achieving optimal performance. The coated components should be heated to the recommended temperature and for the specified duration to ensure complete melting and bonding of the powder particles.

Lastly, it is important to handle the coated components with care to avoid scratching or damaging the coating. Proper packaging and transportation methods should be employed to protect the coated parts during storage and delivery.

In conclusion, aluminum alloy powder coating is an effective surface treatment process that enhances the performance and aesthetics of aluminum alloy components. By following proper cleaning, powder selection, spraying, curing, and handling procedures, high-quality and durable coatings can be achieved.

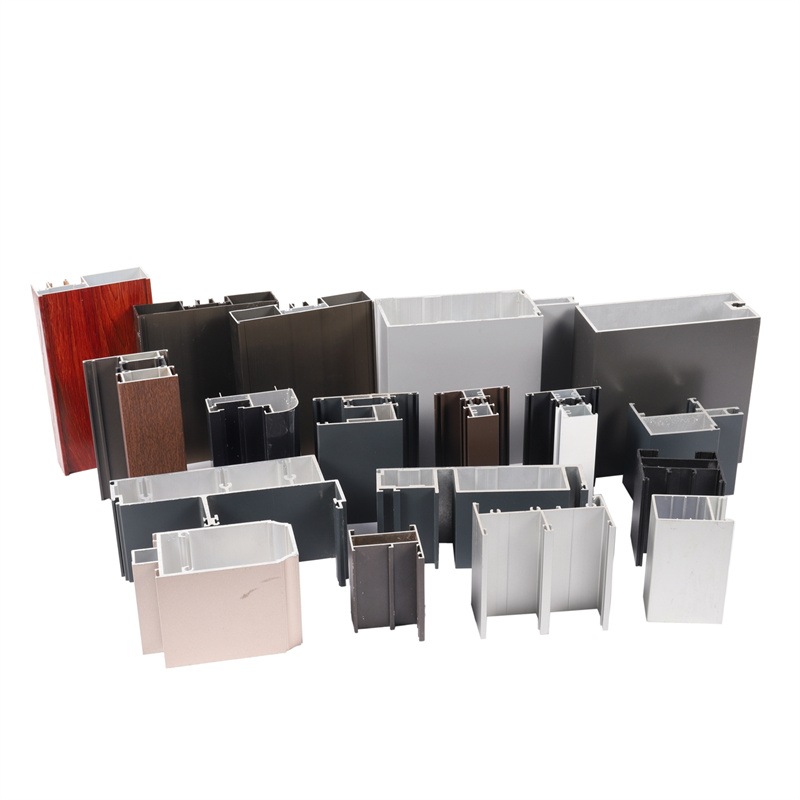

We provide comprehensive aluminum solutions, including design, extrusion, anodizing, powder coating, and various finishes like wood grain and PVDF. Our services also encompass cutting, drilling, bending, welding, punching, and CNC machining, tailored to meet diverse customer needs. Choose our solutions to streamline your project workflow and boost efficiency.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy