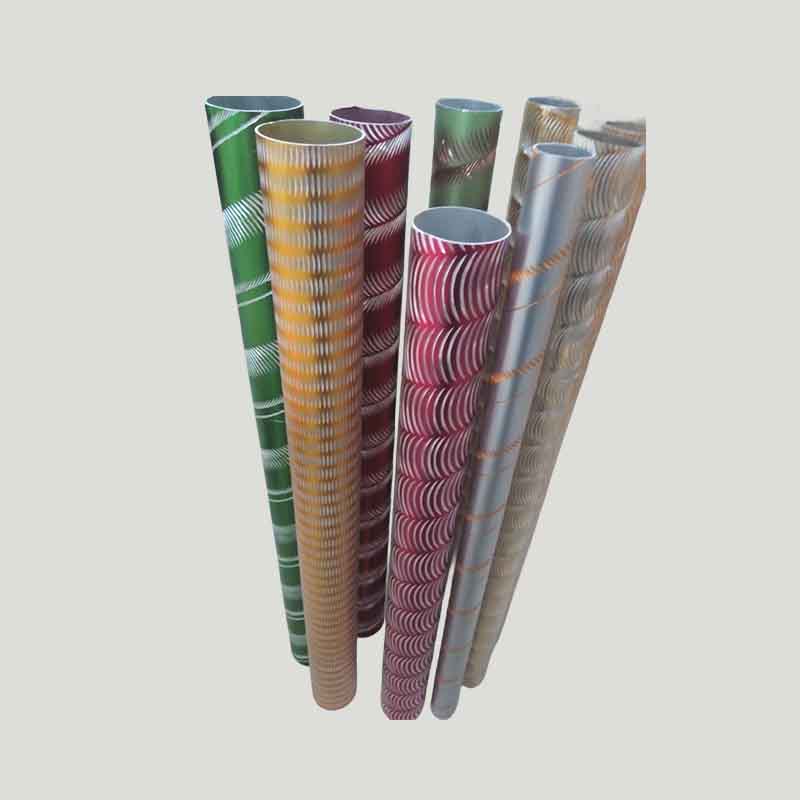

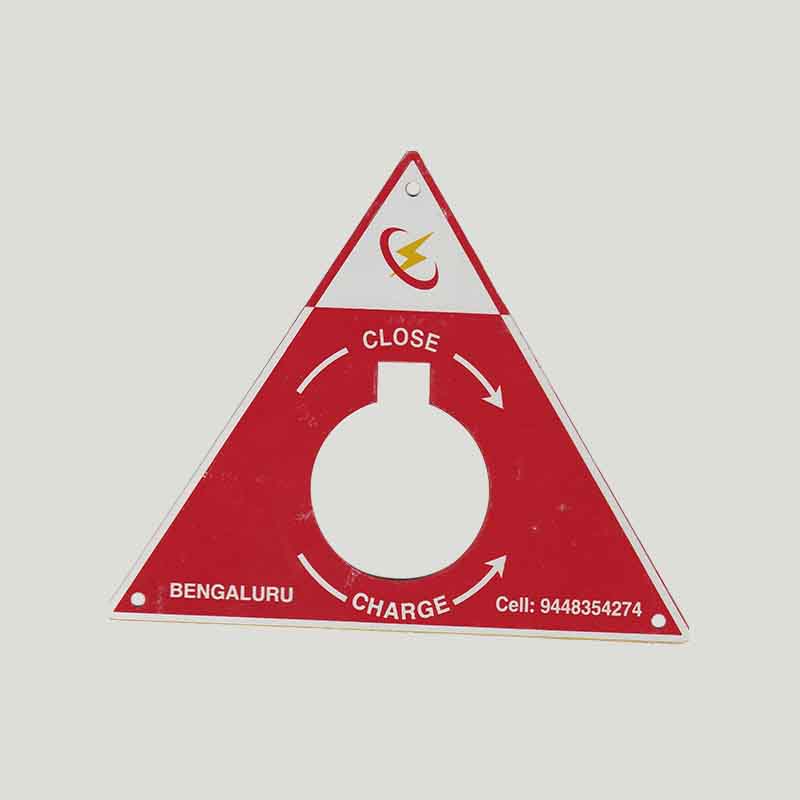

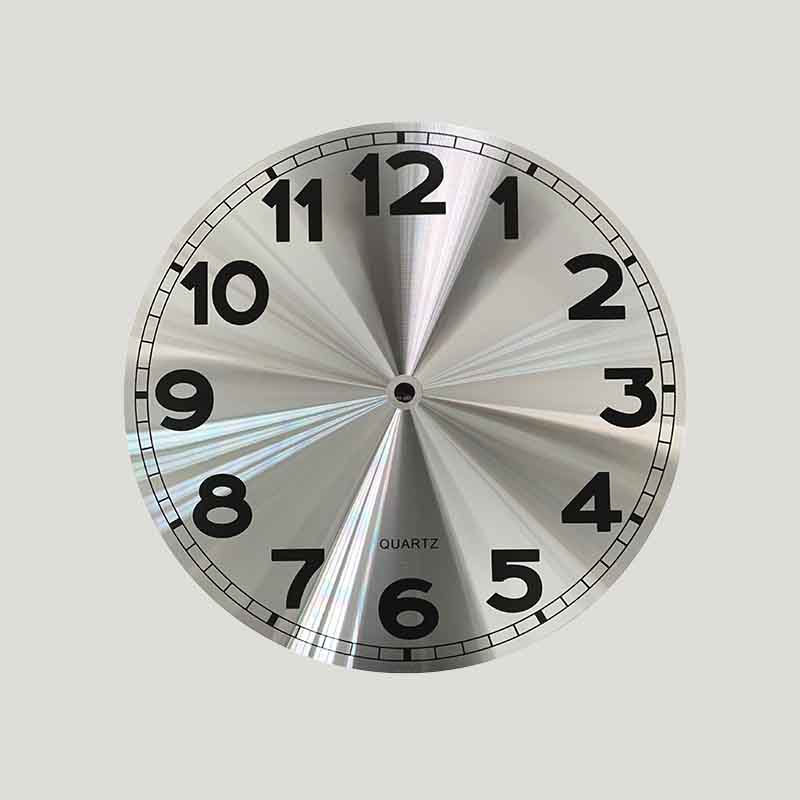

Customized Print Aluminum products are high-quality and customizable products made from aluminum material. Including photo frames, keychains, wall art, nameplates, coasters, and more. Each product can be personalized with your preferred design, color, and text, allowing you to create a unique and memorable item. Using state-of-the-art printing equipment and techniques to ensure vibrant colors, sharp details, and long-lasting prints.

Aesthetic appeal: Brushed aluminum profiles have a unique and modern appearance that adds a touch of elegance to any project. The brushed finish creates a subtle texture that enhances the overall look and feel of the product.

Customized print aluminum products are known for their exceptional durability. Aluminum is a strong and lightweight material that can withstand wear and tear, making it perfect for long-term use.

One of the biggest advantages of customized print aluminum products is the ability to personalize them according to your specific requirements. Whether it’s a logo, design, or text, aluminum products can be easily customized to reflect your brand or individual style.

Customized print aluminum products are highly versatile and can be used in various applications. From signage and displays to promotional items and gifts, aluminum products can be adapted to suit different purposes.

Aluminum is naturally resistant to corrosion, making it ideal for outdoor applications. Customized print aluminum products can withstand exposure to harsh weather conditions, ensuring their longevity and visual appeal.

Aluminum is a sustainable and recyclable material, making customized print aluminum products an environmentally friendly choice. By opting for aluminum products, you can contribute to reducing waste and promoting a greener future.

| Material | Aluminum Alloy |

| Temper | T3-T8 |

| Grade | 6000 Series |

| Length | Customized according to customer requirements |

| Shape | Customized according to customer designs |

| Surface Finish | Brushed |

| Color | Standard: white,black,silver and grey. Can be customized (RAL colors) |

| Packing Details | Kraft Paper, EPE foam, Shrink film, Composite Paper or customized |

| MOQ | 2 tons Lead |

| Time | 30-35 days |

Anodized aluminum profiles are commonly used in architectural applications such as window frames, door frames, curtain walls, and façade cladding. The anodized finish provides a durable and corrosion-resistant surface that can withstand harsh weather conditions.

Anodized aluminum profiles find extensive use in the automotive industry for various applications such as trim, moldings, and decorative parts. The anodized finish enhances the aesthetic appeal of the vehicle while providing protection against scratches and corrosion.

Anodized aluminum profiles are utilized in the furniture and interior design industry for applications such as handles, frames, and decorative trims. The anodized finish offers a wide range of color options and a sleek appearance.

Anodized aluminum profiles are used in the electronics and electrical industry for components such as heat sinks, enclosures, and mounting brackets. The anodized finish improves heat dissipation and provides electrical insulation properties.

Measure and mark the desired location for the profile on the surface where you want to install it. Use a measuring tape and a level to ensure accurate placement.

Place the profile on the marked location and align it properly. Make sure it is straight and level.

Attach the mounting brackets or clips to the profile. These brackets or clips will hold the profile securely in place. Position them along the length of the profile at regular intervals, depending on the size and weight of the profile.

Mark the location of the mounting holes on the surface using a pencil or marker. Ensure that the marks align with the mounting brackets or clips on the profile.

Drill pilot holes at the marked locations using a drill. The size of the pilot holes should be slightly smaller than the screws or bolts you will be using.

Place the profile back on the marked location and align it with the pilot holes.

Insert screws or bolts through the mounting brackets or clips and into the pilot holes. Tighten them using a screwdriver or wrench, ensuring that the profile is securely attached to the surface.

Check the alignment and levelness of the installed profile using a level. Make any necessary adjustments by loosening the screws or bolts and repositioning the profile.

Once the profile is properly aligned and level, tighten the screws or bolts securely.

Repeat the above steps for any additional sections of the anodized aluminum profile that need to be installed.

We are manufacture,we have 14 years experience for supply Metal material and products in domestic.

For smal toolino (Extemal size less than 229mm). t takes about 10-15 days for tooling and about 5 davs for of-tol samples preparino.

We can supply the free sample,but the sample express freight should be by you.

Yes, we will keep you updated about the status here by sending videos or pictures.

You can start with a small trial. Just send me your drawings!

Look forward to hearing from you.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy