Aluminum Tile Trims are highly versatile and exceptionally durable profiles that are specifically designed to offer a sleek, clean, and professional finish to tile installations. These trims find extensive usage in both residential and commercial settings, serving the purpose of safeguarding the edges of tiles while seamlessly bridging the gap between various flooring materials. With their remarkable adaptability and sturdy construction, these trims ensure a flawless transition and add a touch of sophistication to any space.

1.High-Quality Material: Made from premium-grade aluminum, these tile edge trims offer excellent strength, durability, and corrosion resistance, ensuring long-lasting performance.

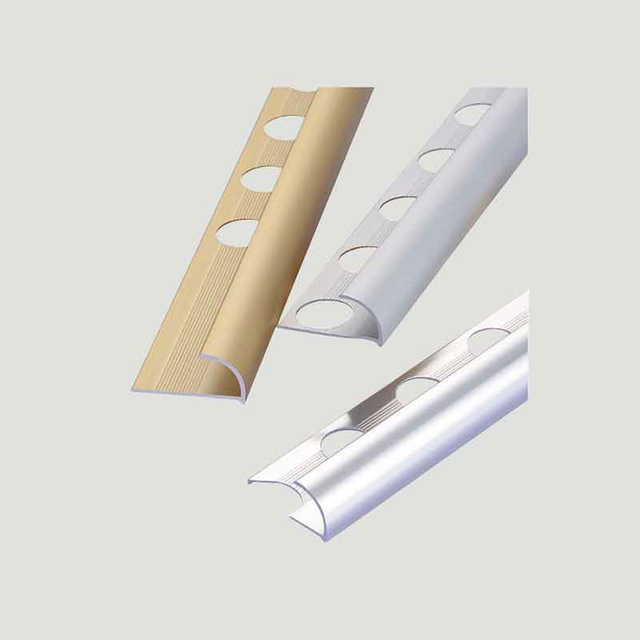

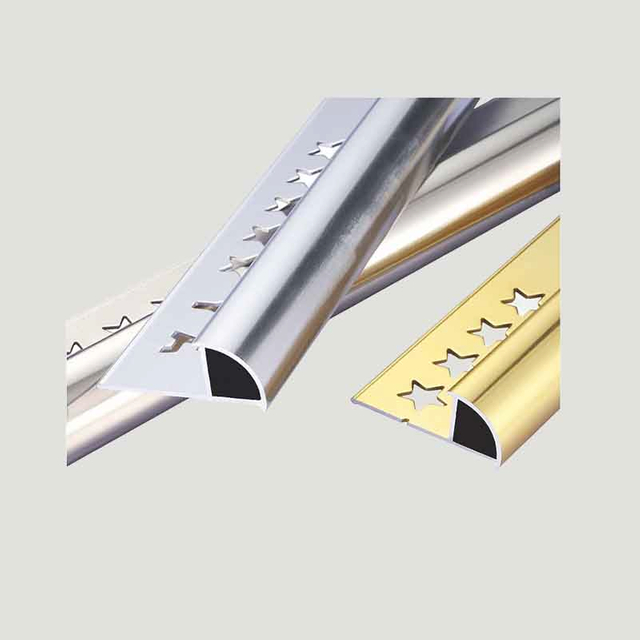

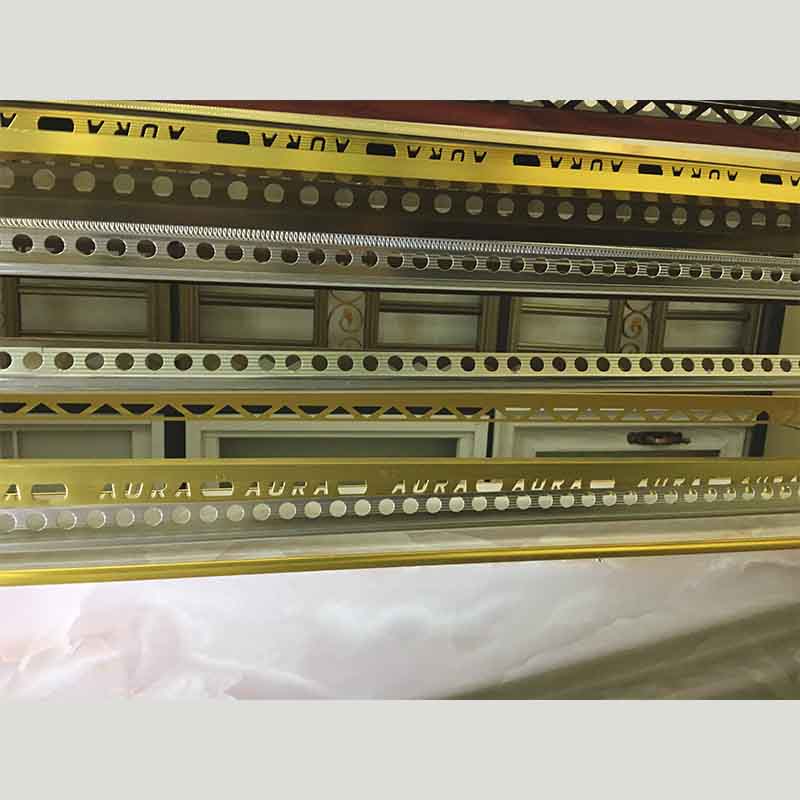

2.Various Profiles: Tile trim profiles is available in a range , including straight edge, round edge, square edge, and L-shaped, to suit different installation requirements and design preferences.

3.Easy Installation: The aluminum tile edging come with pre-drilled holes or adhesive backing for easy and secure installation. They can be easily cut to size using standard tools.

4.Protective Function: The trims provide a protective barrier for tile edges, preventing chipping, cracking, and wear. They also help to minimize grout lines and make cleaning easier.

5.Aesthetic Appeal: The sleek and modern design of the aluminum tile trim adds a decorative touch to tile installations, enhancing the overall appearance of the space.

Aluminum Tile Trims are commonly used in various tile installations, both residential and commercial. Some common applications include:

1.Bathroom: Aluminum tile trims can be used to protect the edges of tiles in bathroom walls and floors, providing a clean and finished look.

2.Kitchen: They are also suitable for kitchen backsplashes, countertop edges, and tile transitions, ensuring a neat and professional appearance.

3.Living areas: Aluminum tile trims can be used in living rooms, dining rooms, and other areas where tiles are installed. They help protect the edges of the tiles from chipping or damage.

4.Commercial spaces: These trims are widely used in commercial spaces such as hotels, restaurants, offices, and retail stores. They provide a polished and professional finish to tile installations.

5.Swimming pools: Aluminum tile trims are resistant to moisture and can be used in swimming pool areas to protect the edges of tiles from water damage.

6.Outdoor areas: They are also suitable for outdoor tile installations, such as patios, balconies, and walkways, as they are durable and weather-resistant.

Overall, Aluminum Tile Trims are versatile and can be used in various applications where tile edge protection and a clean, finished look are desired.

| Material | Aluminum |

| Color | Various options available |

| Length | Customizable |

| Width | Customizable |

| Thickness | Customizable |

| Surface Finish | Anodized, brushed, polished, powder coated etc |

| Shape | Various shape available |

| Usage | Tile edge protection |

| Installation | Screw or adhesive |

| Features | Durable, corrosion-resistant, easy to clean |

| Application | Residential and commercial tile installations |

| Packaging | Standard carton packaging |

| MOQ | 500 pieces |

| Lead Time | 15-20 days |

| OEM/ODM | Available |

1.Before starting the installation process, ensure that you have all the necessary tools and materials, including a measuring tape, pencil, hacksaw, adhesive, and a trowel.

2.Measure the length of the area where the tile trim will be installed and mark the desired length on the trim using a pencil.

3.Use a hacksaw to cut the trim to the desired length. Make sure to wear safety goggles and gloves while cutting.

4.Apply adhesive to the back of the trim using a trowel. Make sure to spread the adhesive evenly across the entire back surface.

5.Press the trim firmly onto the edge of the tile, making sure it is aligned properly. Apply pressure to ensure a secure bond between the trim and the tile.

6.Repeat the above steps for each section of the tile trim, ensuring that they are installed evenly and aligned properly.

Allow the adhesive to dry completely before grouting the tiles.Once the adhesive is dry, apply grout to the gaps between the tiles, including the area where the trim is installed. Use a grout float to spread the grout evenly and remove any excess.Clean the surface of the tiles and the trim with a damp sponge to remove any grout residue.

Finally, inspect the installed tile trim for any gaps or unevenness. If necessary, apply additional adhesive or grout to fill in any gaps or correct any imperfections.

Our normal thickness is about 10 um. Yes, we can do 15um and above.

We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy