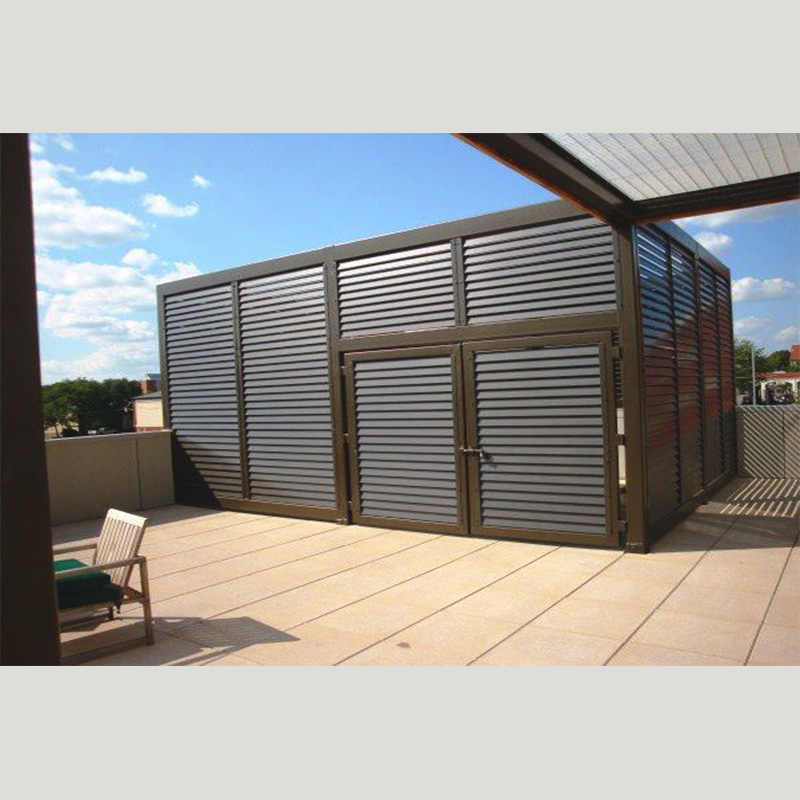

Panel fencing is an aluminum grid structure usually consisting of two transverse beams and a number of vertical slats. Among them, the vertical slats are spaced at a certain distance, so that the fence has a certain perspective, and also has a certain aesthetic quality. The fence of this structure is easy to maintain, fixed and stable, and has a long service life.

An aluminum fence is a highly durable, stylish option for homeowners looking to define their yard without blocking the view.

1 The Versatility of Aluminum Fencing

You can place an aluminum fence just about anywhere.

2 Our fences are designed to conform to the terrain of your backyard without hassle. They can run over an uneven perimeter with minimal effort — no terraforming required for most installations. Even when you’re working with uneven ground, we can ensure you’ll love the look of your aluminum fence. It’ll look professional, clean, and beautiful.

The ‘Rackable’ Aluminum Fence

Our aluminum fences are versatile because they implement a “rackable” design.

3 luminum Fences Stand Firm

The aluminum fences we install are made to last. Many other fences on the market deteriorate over time, but ours resist some of the harshest environments. You can enjoy your fence for many, many years.

4 Aluminum is one of the sturdiest fencing materials on the market today. The powder coatings boost its weather-resistant properties and will counter chipping, peeling, or cracking. That’s why aluminum fencing withstands sweltering summers and bitter winters, with torrential wet seasons in between.

These are some of the most durable fences on the market today. Unlike materials like iron or steel, aluminum fences resist rust and corrosion.

Aluminum alloy guardrails originated in Europe, and are enclosure components at the edges of buildings such as buildings, platforms, corridors, and ladders. They have protective functions and also play a decorative role. It has been widely used as early as the 1970s, and certain industry standards have been formulated. It has also experienced more than 20 years of development in our country. Due to its light weight, high strength, good performance, strong decoration, economy and durability, no pollution, and recyclability, it has become the main guardrail product in my country’s public transportation, community parks, building construction, etc., and is in the diversified product system of the guardrail industry. , Aluminum alloy guardrails are still very popular.

| Product Name | Aluminum slat fence and gate |

| Material | aluminum 6063-T3 |

| Slat size | 65*16mm/100*16mm/150*16mm |

| Slat gap | 10/15/20/30mm/customized |

| Surface treatment | wood grain/powder coating |

| Assembly method | welded/pre-assemble/Diy |

Measure the original ground elevation of the fence installation section, if the ground undulation is not large, you can properly adjust the fence

The depth of the fence pit is used to unify the horizontal elevation of the columns. When the ups and downs are large, the slope protective fences shall be set up collectively.

Before installing the protective fence, the ground on both sides of the fence should be leveled and compacted.

When there is a height difference on both sides of the slope or the fence, the raised part within 2m on both sides of the fence should be

For leveling, the ground on both sides should be at the same height and not higher than the bottom of the lower sill of the fence to ensure that the fence

The protective height is reached relative to the ground on both sides.

Excavate the column foundation pit according to the measurement stakeout position and elevation, and the foundation pit should be excavated vertically.

The size of the foundation pit shall meet the design requirements, and the undisturbed soil on the side of the foundation pit shall not be disturbed.

General soil section, foundation bearing capacity ≥ 100kPa, resistance to lateral stress ≥ 60kPa

The foundation is poured with C25 concrete. The base size of the 1.8m high protective fence adopts

600mmx600mmx700mm, the base size of the protective fence in the slope area adopts

600mmx600mmx900mm. The disturbed soil should be excavated and backfilled, and the compaction coefficient of the backfilled soil is not

less than 0.93.

Upright posts, upper sills, lower sills and post caps should be protected during transportation, with straw mats,

Straw, sawdust or other cushioning and shockproof materials, the number of stacked layers shall not exceed five layers, and the height shall not exceed

More than 600mm. The metal mesh and connecting components are protected by effective packaging to prevent bumps.

Reinforced concrete fences should be arranged vertically with cushioning materials in them to prevent bumps.

After digging the foundation pit, when embedding the columns, the position and elevation should be strictly controlled, and measured with a ruler.

Measure its verticality and measure its height with a tape measure. After confirming that it meets the requirements of the construction drawing, use a temporary support

The support is fixed, and the column is not displaced vertically and horizontally. The foundation is poured with C25 concrete.

The column support can be removed only after the concrete strength reaches 70% of the design strength.

After the strength of the concrete foundation reaches more than 80% of the design, install the lower sill, fence, upper

C30 fine concrete or M30 cement sand should be used for the gap between the sill and column cap, the upper and lower sill and the fence piece

The grout is filled to form a solid whole, and there must be no shaking of the fence after fixing.

The connecting bolts between the column cap and the column should be tightened with a socket wrench, and the top should be filled with cement mortar.

When the upper sill is connected with the uphill column, first inject C30 water into the round hole reserved on the upper sill

Mud mortar (mixed with quick-setting agent), penetrate the roughened end of the screw through the reserved hole of the column, with mortar

After solidification, it is fastened. After the fastening is completed, the reserved holes on the columns are filled with cement mortar.

Our normal thickness is about 10 um. Yes, we can do 15um and above.

We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy