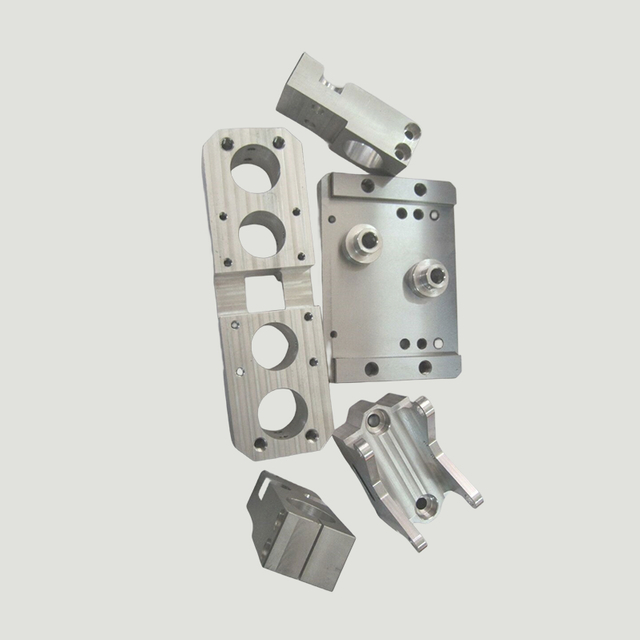

1.Description:Aluminium Auto Parts

2. Alloy temper: 6063-T6; 5083-H112; 6061-T6/T651; 6082-T6/T651; 6351-T6; 7075-T6

3. Standard: EN755, ASTMB221, DIN Standard

4. Surface treatment: Mill finish; Anodizing; Powder coated, Brushed.

5. Application:Window, door, curtain wall, decoration ;Car; Aerospace; Ship; Armarium; Industrial equipment; And etc.

6. Advantage:

1) Pure 99.7% aluminum materials without any scrap used

2) OEM welcome, we can design and cut die to meet customer’s special demand

3) Wonderful surface treatment, we can meet customers required on surface

4) Strictly quality control process assured higher quality.

5)Hard alloy longer life span

6) Packing safety and convenient.

| Product category | CNC machining part | ||||||

| Material available | Stainless steel, aluminum, copper, alloy steel, PTFE, PEEK, nylon, etc. | ||||||

| Surface treatment | Anodizing, Sandblasting, Heat treatment, Polishing, Powdering, PVD coating, electroplating, silkscreen etc. | ||||||

| Tolerance | ± 0.01mm | ||||||

| Quality control | 100% inspection before shipment | ||||||

| Experience | 15 years of professional OEM service | ||||||

| Packaging | Polybag + carton box + pallet, or as per customers’ requirement | ||||||

| Lead time | 3-5 days for sample, and 30 days for mass production generally. It can be adjusted according to customers’ request. | ||||||

| Term of payment | T/T, PayPal, etc. | ||||||

| File formats | Pro-E, Solid Works, AutoCAD, PDF, or others. | ||||||

| OEM customized aluminum profiles are available | |||||||

Professional quality inspection, professional quality inspection personnel, many years of experience in quality control, with 3D measuring instrument, to provide quality inspection reports for products; the company passed ISO9001:2000 quality embodiment certification, we always adhere to the business philosophy of “quality is life”; VS testing tools are single: quality cannot be effectively guaranteed, unable to issue test reports.

Our normal thickness is about 10 um. Yes, we can do 15um and above.

We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy