The two most prominent reasons aluminum is so indispensible to the aerospace industry have already been mentioned. As one of the metals with the highest strength to weight ratio, it’s value to the aerospace industry is obvious. Airframes must be strong and durable enough to withstand the stresses of takeoffs and landings over time. At the same time, if the metal is too heavy, this will require more fuel to be consumed during flights. This means that aluminum is often the most cost-effective choice for aircraft.

Strength and weight are not the only advantages of aluminum; another major benefit of aluminum alloys is their corrosion resistance. This is a major factor in the durability of an aircraft. Airplanes are constantly subject to the elements and regularly experience climactic extremes; freezing temperatures found at high altitudes and exposure to all sorts of precipitation, including snow and rainstorms. Aluminum is famous for its ability to withstand environmental corrosion.

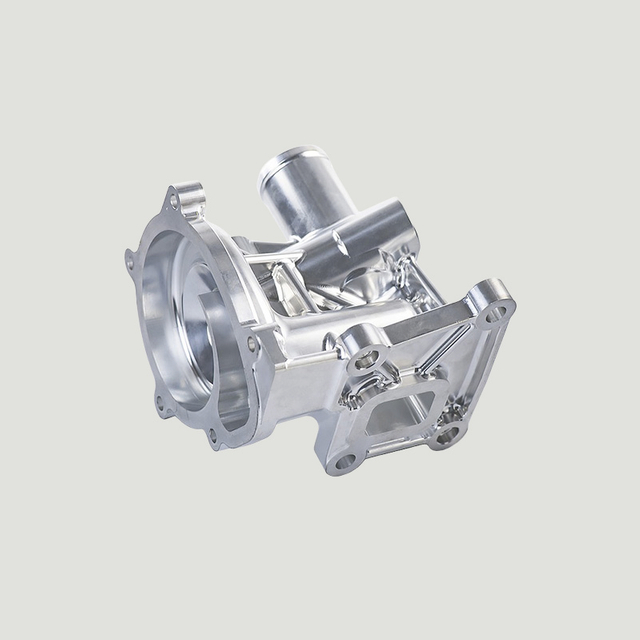

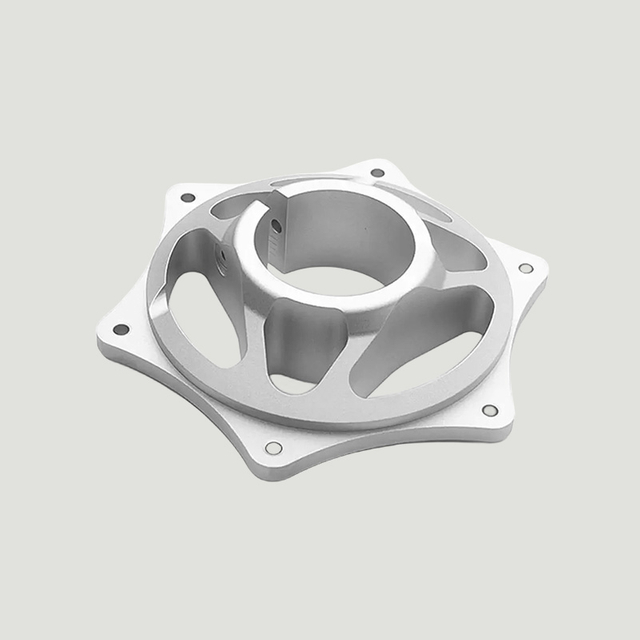

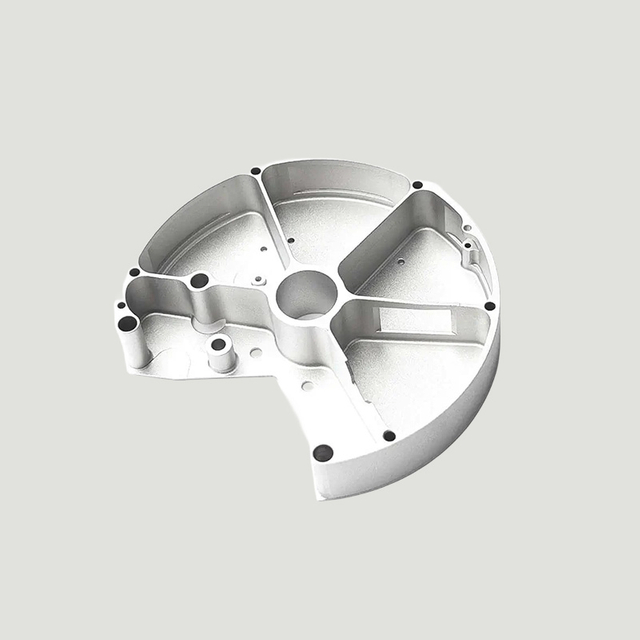

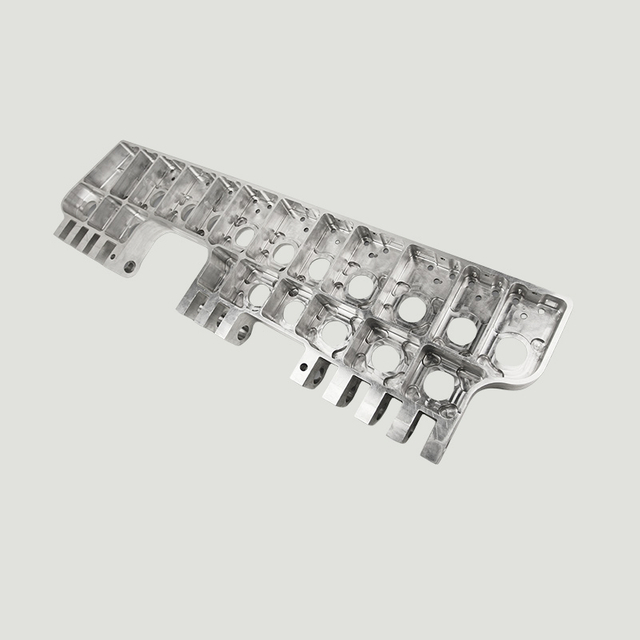

Furthermore, aluminum also happens to be extremely formable. This is a blessing for the aircraft industry, which requires a high degree of precision to ensure maximum aerodynamics, not to mention all of the small parts that can be found on aircraft. Aluminum’s ease in fabrication and machining makes it another area in which it offers cost savings over alternative materials.

Aluminum is also aesthetically pleasing; while this is not the most important consideration, it doesn’t hurt since no one wants to fly in a vehicle that isn’t visually attractive (with perhaps the Millennium Falcon as the only exception).

It’s been estimated that 80% of all metal content in aircraft today is aluminum; it’s easy to see why.

| Available materials Steel | carbon steel, alloy steel, stainless steel, 4140,20#,45# ,40Cr,20Cr ,etc | ||||||

| Aluminum | AL6061,AL6063,AL6082,AL7075,AL5052 etc. | ||||||

| Stainless steel | 201SS,301SS,304SS,316SS etc. | ||||||

| Brass | C37700,C28000, C11000,C36000 etc | ||||||

| Plastics | PTFE,PEEK,POM,PA,UHMW, NYLON | ||||||

| Size | Customized | ||||||

| Surface treatment | Powder coating, electroplating, oxide,anodization | ||||||

| Technics | laser cut, bend, weld, stamp | ||||||

| OEM | Accept | ||||||

| Drawing Format | 3D/CAD/Dwg/IGS/STP | ||||||

| Color | Customized | ||||||

| Application | Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications | ||||||

| OEM customized aluminum profiles are available | |||||||

Benefits of Aluminum Firearm Parts over Steel Firearm Parts

7075, 7050, and 7158 are all aluminum alloy used in applications that require high strength like firearm mechanisms, firearm pieces, and more. It is widely recognized for its high strength, and toughness. This alloy come’s in plate form and several shapes, rounds, hex and square bar. Overall, the 7xxx products are used to manufacture products and equipment/machinery that require a high strength-to-density ratio.

7xxx are known as one of the strongest aluminum alloys available and has an excellent weight-to-strength ratio, making it used for parts with high stresses. These metals can form in an annealed condition and has greater spring back when formed. It’s possible to form this metal when it is in the annealed condition. Heat treatment can be used to increase the strength of 7xxx alloys and has excellent properties when in lower temperatures.

Our normal thickness is about 10 um. Yes, we can do 15um and above.

We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy