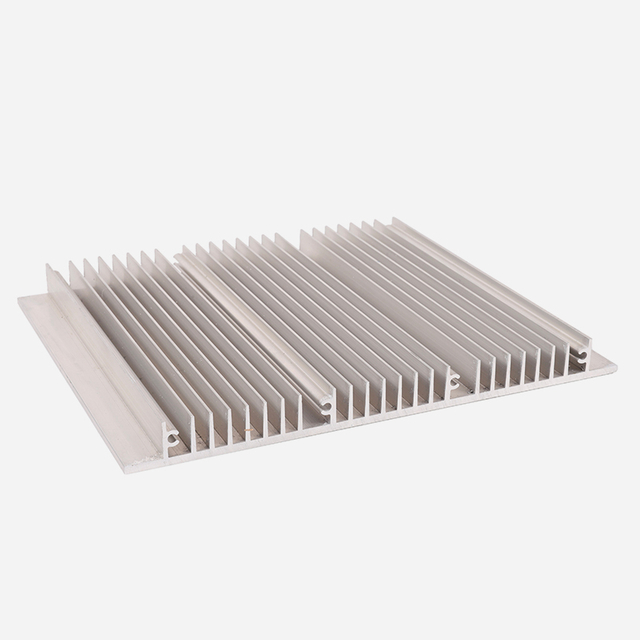

A heat sink is designed to maximize its surface area in contact with the cooling medium surrounding it, such as the air. Air velocity, choice of material, protrusion design and surface treatment are factors that affect the performance of a heat sink. Heat sink attachment methods and thermal interface materials also affect the die temperature of the integrated circuit. Thermal adhesive or thermal paste improve the heat sink’s performance by filling air gaps between the heat sink and the heat spreader on the device. A heat sink is usually made out of aluminium or copper.

You will find that V-Slot is perfect for most projects. Below is a list of a few ideas to get you started. You are the creator. Have fun with it!

| Alloy | 6063 | 6061 | 6060 | 6005 | 6082 | 6463 | 7075 |

| Temper | T5 | T6 | T4 | ||||

| Standard | DIN | AAMA | As | CHINAGB | |||

| Certification | IS09001:2008. | ||||||

| Surface finish | Mill finish | Anodizing | Powder Coating | Wood Grain | Electrophoresis | Polished | Brushed |

| Color | Anodizing: | Silver, bronze, champagne, titanium, nickel, golden yellow, etc | |||||

| Anodizing thickness is up to 25um | |||||||

| Powder coating: | White, black, bronze, grey, green, etc | ||||||

| Powder coating thickness is more than 60um | |||||||

| Wood grain: | 1. Italian MENPHIS transfer printing paper. | ||||||

| 2. AKZO NOBEL INTERPON D1010(10 years warranty): Australia ceder, Bush cherry, Chest nut, Jarrah l, Jarrah ll, Western red ceder, etc. | |||||||

| 3. AKZO NOBEL INTERPON D34(5 years warranty): Bush wood, Western red, Jarrah. Snow gum, etc. | |||||||

| Electrophoresis: | Silver, nickel, golden yellow, black, champagne, etc | ||||||

| Polishing: | Silver, nickel, golden yellow, black, etc | ||||||

| Brushing: | Silver, nickel, golden yellow, black, bronze, etc | ||||||

| Machining | Cutting, punching, drilling, bending, weld, mill, CNC, etc | ||||||

| OEM customized aluminum profiles are available | |||||||

Our normal thickness is about 10 um. Yes, we can do 15um and above.

We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements.

Take the first step, We will get back to you within 24 Hours

Starting from here, we will jointly create a glory. We are progressing toward a promising future. With our aluminum and craftsmanship

305#, Floor 3, Fengdong Nanfang Commerical Center Bld A, Fengchi, Dali, Nanhai, Foshan, Guangdong, 528231, China

Copyright © 2025 Brilliance. Sitemap | Privacy Policy